Home

Why to choose Tecnoplastica?

Tecnoplastica Reatina originates from a passion for thermoplastic materials and their endless possibilities of transformation. For over forty years, we have been a leader in the injection molding sector and in the design and construction of molds, serving as a dedicated partner to major European and international industrial entities.

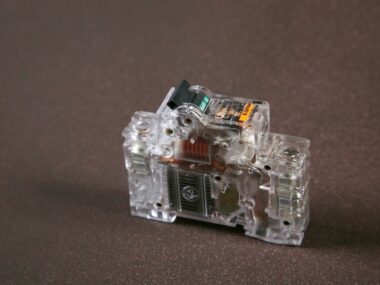

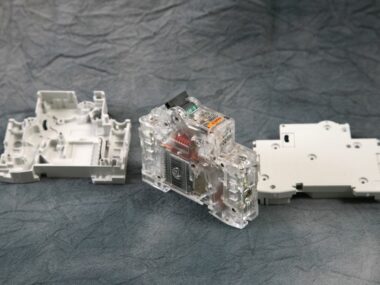

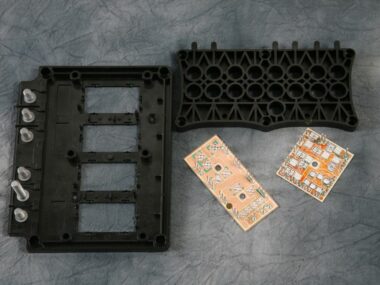

By collaborating with internationally renowned industries, primarily in technical sectors such as Mechanical, Chemical, Electronic, and Electrotechnical, we address their specific needs for special materials and an exceptionally professional molding process.

Our

Workflow

Needs Analysis

Identification of the most suitable material starting from the project, analyzing the geometry, and considering the customer’s requirements.

Project Development

3D design, co-design, and collaboration with the customer to optimize the mold design. Mock-ups in rapid prototyping.

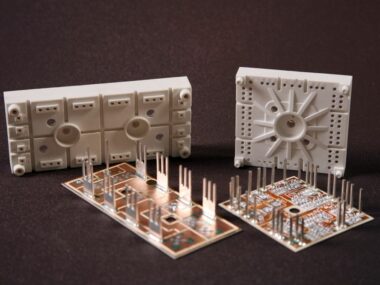

Mold manufacturing

After meticulous design aimed at anticipating every possible variable, the mold is produced using state-of-the-art numerical control machines.

Moulding

Production relies on a machine park of technologically advanced injection molding presses, with closing forces up to 2,800 kN and a maximum printable weight of up to 800 grams.

+

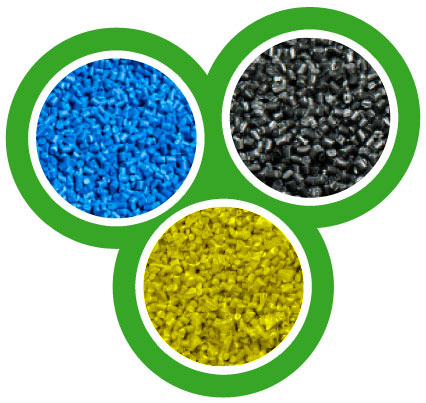

High-Quality Materials

In all our creations, we exclusively use special thermoplastic materials and high-performance technopolymers, all certified and sourced from selected suppliers.

We shape your projects

With 7000 square meters of surface area and a production capacity that spans 3 shifts (24 hours), we are ready to meet any customer request. Our machine park comprises 22 presses, all technologically advanced and automated. The pressing capacity of the machines ranges from 40 to 280 tons, with a maximum printable weight of 800 grams.

The Tecnoplastica Reatina team is at your disposal!